In today's competitive market, the importance of selecting the right plastic packaging boxes cannot be overstated, especially when it comes to ensuring product safety. According to a recent report by Smithers Pira, the global market for plastic packaging is expected to reach $1 trillion by 2024, highlighting the critical role that packaging plays in safeguarding products throughout the supply chain. The right packaging not only protects products from damage during transit but also enhances shelf life and ensures compliance with safety standards. Moreover, with increasing consumer awareness about sustainability, choosing eco-friendly plastic packaging options has become a vital consideration for businesses aiming to meet market demands. Therefore, understanding the essential criteria for selecting plastic packaging boxes is crucial for companies seeking to maximize product safety and maintain customer satisfaction.

When selecting plastic packaging materials, several critical factors must be taken into account to ensure product safety and environmental sustainability. The type of plastic used is one of the most significant considerations. Various materials, such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP), each possess distinct properties that affect their suitability for different applications. According to the Global Recycled Plastics Market report, the market size is expected to grow significantly, indicating increasing demand for sustainable options in packaging.

Moreover, the composition and compatibility of the packaging with the product can influence not only the safety and integrity of the goods but also the packaging's environmental impact. The demand for biodegradable and recyclable materials is on the rise, with projections in the bioplastics market suggesting an estimated compound annual growth rate of 39.9% from 2024 to 2032. Therefore, businesses should evaluate the lifecycle of their selected materials and consider innovative options that reduce their carbon footprint while ensuring effective protection of their products during storage and transit.

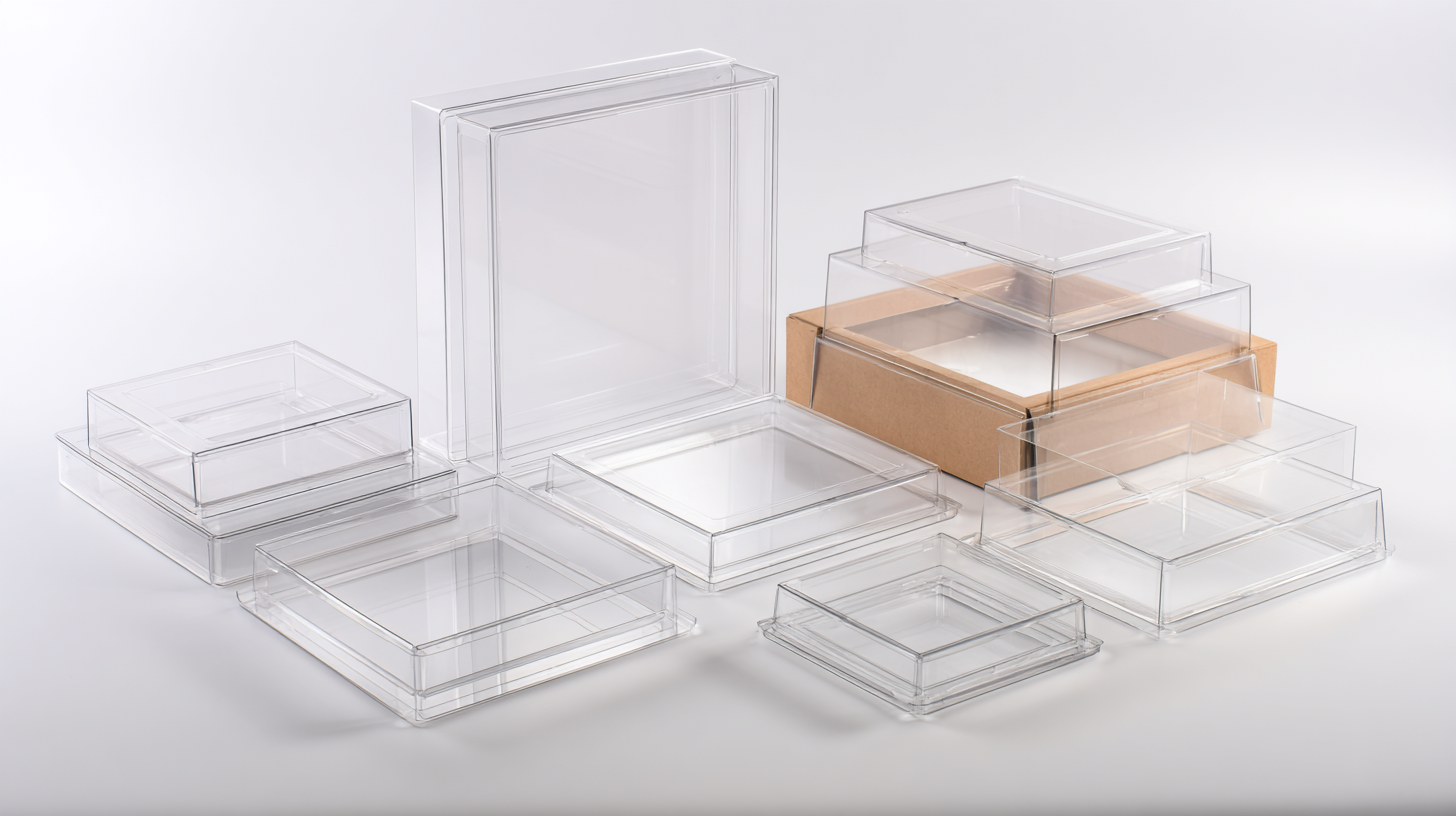

When choosing the right plastic packaging boxes, understanding the various types of plastic options available is crucial. Each type of packaging serves specific functions and is tailored for different products, which impacts product safety and overall effectiveness. Common plastic materials include polyethylene (PE), which is ideal for its flexibility and moisture resistance, and polyethylene terephthalate (PET), known for its strength and clarity. These materials are often used in boxes designed for food, pharmaceuticals, and other sensitive items that require durability and protection from environmental factors.

The packaging market is continually evolving, with significant growth projected across various segments. For instance, the sterile pharmaceutical packaging market is expected to grow substantially, achieving a market value of $19.41 billion by 2032. Additionally, the frozen food packaging sector is also seeing considerable expansion, reflective of changing consumer demands for convenience and safety. As eco-friendly initiatives gain momentum, innovative sustainable packaging solutions are emerging, emphasizing the importance of environmentally conscious choices in enhancing product safety and sustainability in the packaging industry.

The evaluation of packaging design significantly influences product safety, especially in the medical device sector. The release of the draft guidelines for the registration review of human factors design by the Medical Device Technology Review Center is a critical step in standardizing submission materials and review requirements. This initiative aims to enhance the safety and efficacy of medical devices by ensuring that packaging is designed with the user in mind, minimizing risks associated with misuse or misunderstanding.

Packaging design plays a pivotal role in protecting products from contamination, damage, and misuse. By adopting a human-centered design approach, packaging can be tailored to guide users effectively, thereby reducing the probability of errors during device handling. Clear labeling, intuitive design features, and robust materials can significantly mitigate risks, ensuring that the medical devices remain safe throughout their lifecycle. As these guidelines are finalized, they will help manufacturers align their packaging strategies with best practices, ultimately promoting greater patient safety and product reliability in the healthcare industry.

When selecting plastic packaging boxes, assessing supplier reliability and quality assurance practices is paramount. A reliable supplier not only provides high-quality packaging solutions but also ensures that their products adhere to safety standards. One of the first tips to consider is to thoroughly research potential suppliers. Look for customer reviews and case studies that demonstrate their ability to deliver on promises, as well as their track record in maintaining product integrity.

Another crucial aspect is to inquire about quality assurance protocols. Choose suppliers that implement rigorous quality control measures, such as regular testing of materials and final products. This helps to ensure that the plastic packaging will withstand transportation and storage conditions, safeguarding the contents effectively. Additionally, consider suppliers with certifications that validate their commitment to quality, such as ISO certifications or compliance with FDA regulations.

Finally, establish clear communication with your chosen supplier. A dependable supplier should be open to discussing their quality assurance practices and provide transparency regarding their sourcing of materials. This level of openness can enhance your confidence in their ability to deliver packaging solutions that prioritize product safety while meeting your specific needs.

When selecting plastic packaging boxes, sustainability should be a key consideration that underpins every decision. The environmental impact of plastic packaging has gained significant attention, prompting brands to seek materials that not only protect their products but also minimize ecological footprints. Choosing recyclable or biodegradable plastics is essential in this regard, as these options contribute to reducing landfill waste and promoting a circular economy. Manufacturers and consumers alike must prioritize materials that can be easily repurposed, thus supporting a more sustainable approach to packaging.

Moreover, the sourcing of raw materials plays a crucial role in sustainability. Opting for suppliers that utilize recycled content can further enhance the environmental benefits of plastic packaging. It's also important to look for certifications or eco-labels that indicate a commitment to sustainable practices. Additionally, designs that minimize material usage without compromising product safety can significantly reduce the overall environmental impact. By making informed choices about plastic packaging, businesses not only fulfill their responsibility to the planet but also appeal to a growing segment of eco-conscious consumers.

| Tip | Description | Sustainability Consideration | Safety Feature |

|---|---|---|---|

| 1. Choose Recyclable Materials | Opt for plastic packaging that can be easily recycled after use. | Reduces landfill waste and promotes a circular economy. | Avoids harmful chemicals that may leach into products. |

| 2. Assess Material Durability | Select packaging materials that can withstand transport and handling. | Less frequent replacements reduce resource consumption. | Prevents damage that could compromise product safety. |

| 3. Consider Size Optimization | Choose packaging sizes that fit products snugly to minimize waste. | Reduces material use and transportation emissions. | Lowers risk of movement inside the packaging, ensuring product integrity. |

| 4. Look for Certifications | Choose packaging with certifications that indicate safety and sustainability. | Provides assurance on environmental impact and safety standards. | Ensures compliance with safety regulations for food and other sensitive products. |

| 5. Investigate Source and Lifecycle | Research the source of the plastic and its lifecycle from production to disposal. | Encourages responsible sourcing practices and better end-of-life options. | Ensures packaging does not pose long-term risks to consumers or the environment. |