When it comes to shipping goods, selecting the right carton boxes is crucial for ensuring the safety and integrity of your products. According to packaging expert John Smith, “The right carton box not only protects your items but can also enhance your brand’s visibility during transit.” With a myriad of options available in the market, understanding the key features and benefits of different types of carton boxes can significantly impact your shipping efficiency and cost-effectiveness.

In this guide, we will explore the various factors to consider when choosing carton boxes for your shipping needs, such as material strength, size, and design. Whether you are shipping fragile items or bulk goods, the right carton box will help you mitigate risks associated with damage and returns. By delving into expert insights and best practices, we aim to equip you with the knowledge necessary to make informed decisions that align with your shipping strategy.

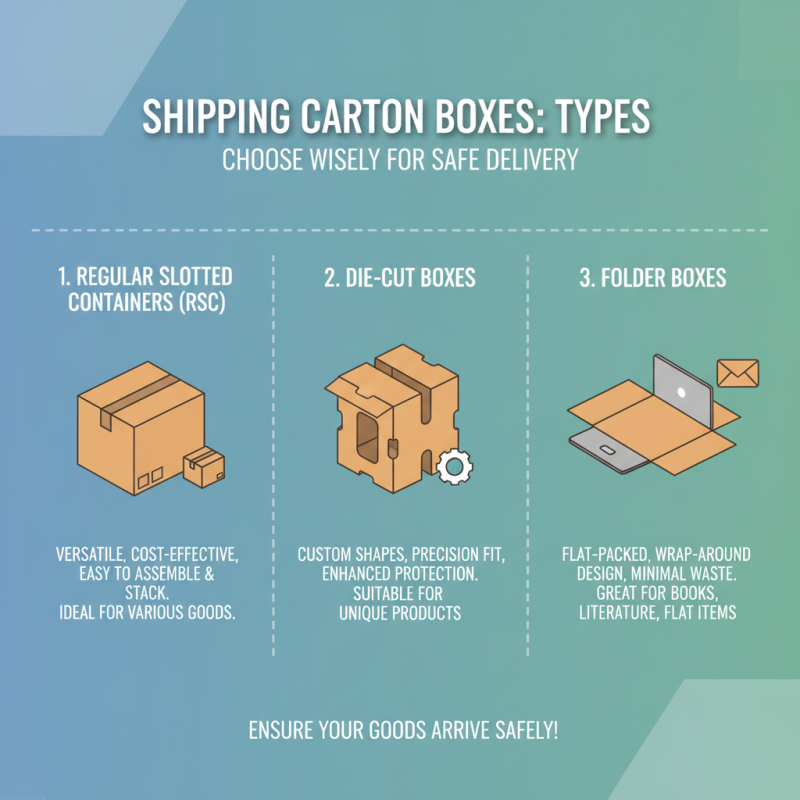

When selecting carton boxes for shipping, understanding the various types available is crucial to ensuring that your goods arrive safely and efficiently. The most common types of carton boxes include regular slotted containers (RSC), die-cut boxes, and folder boxes. RSCs are versatile and cost-effective options, with their standardized shape making them easy to assemble and stack. They are ideal for a wide range of products, from lightweight items to heavier goods that require additional protection.

Die-cut boxes offer a more tailored solution, as they can be manufactured in specific shapes and designs suited to the product's dimensions. This type of box minimizes movement during transit, reducing the risk of damage. Additionally, folder boxes are commonly used for flat items and provide a lightweight but sturdy option. Their design allows for easy loading and retrieval of contents, making them perfect for documents, books, or promotional materials. Each type of carton box serves distinct shipping needs, making it essential to evaluate the nature of the products you will be shipping to make an informed decision on the best option.

When selecting carton boxes for shipping, evaluating their strength and durability is essential to ensure the safe transport of goods. According to the American Society for Testing and Materials (ASTM), carton boxes are often tested based on several criteria, including the edge crush test (ECT) and the bursting strength test. ECT measures the box’s ability to withstand vertical forces, making it critical for stacking during transit. A box with a minimum ECT of 32 (or higher) is generally recommended for shipping heavier items to prevent collapse.

In addition to the ECT, the bursting strength of a box—which indicates how much pressure it can endure before breaking—is equally crucial. The Fiber Box Association reports that a box with a bursting strength of at least 200 pounds per square inch (PSI) is optimal for securing items during shipping. It's also beneficial to consider factors like the type of corrugated cardboard used, as single-wall, double-wall, or triple-wall options vary significantly in strength. A recent study published by the Packaging Association highlighted that nearly 30% of shipments experience damage due to inadequate packaging, reinforcing the importance of selecting the right carton based on strength and durability parameters.

When it comes to shipping products, choosing the right carton box size is crucial to ensure both safety and cost-efficiency. Accurately calculating the dimensions of the carton box based on the product's measurements can significantly reduce the risk of damage during transit. According to a study by the Protective Packaging Association, 40% of shipment damage can be attributed to improper packaging sizes. Therefore, taking precise measurements of the product, including length, width, and height, is essential to select a box that accommodates the item snugly without excessive empty space.

To determine the appropriate carton box size, it is vital to allow for some additional space to account for padding materials such as bubble wrap or packing peanuts. Industry standards suggest adding at least 2 to 3 inches to each dimension of the product for cushioning. This rule of thumb ensures that fragile items remain secure in transit while preventing movement within the box. The International Safe Transit Association reports that an optimal fit can decrease the likelihood of damage and significantly reduce shipping costs by minimizing dimensional weight charges. Keeping these guidelines in mind can help in selecting the best carton box for your specific shipping needs, thereby enhancing the overall efficiency of your shipping operations.

| Product Type | Dimensions (L x W x H, inches) | Weight (lbs) | Recommended Carton Size (inches) | Carton Type |

|---|---|---|---|---|

| Electronics | 15 x 10 x 5 | 3.5 | 16 x 11 x 6 | Single Wall |

| Apparel | 20 x 15 x 2 | 1.2 | 21 x 16 x 3 | Double Wall |

| Books | 12 x 9 x 6 | 2.0 | 13 x 10 x 7 | Single Wall |

| Fragile Items | 10 x 10 x 10 | 2.5 | 12 x 12 x 12 | Double Wall |

| Toys | 18 x 12 x 6 | 1.8 | 19 x 13 x 7 | Single Wall |

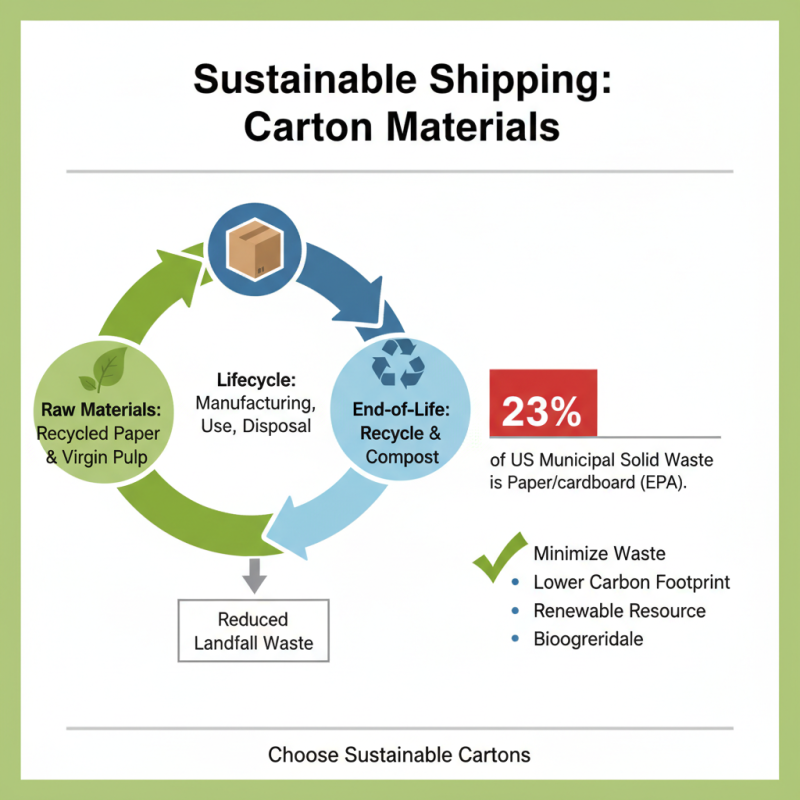

When evaluating the environmental impact and sustainability of carton materials for shipping, it is crucial to consider both the raw materials used and the lifecycle of the packaging. According to the Environmental Protection Agency (EPA), paper and cardboard account for approximately 23% of municipal solid waste in the United States. This statistic underscores the importance of choosing sustainable carton boxes that can minimize waste and reduce the carbon footprint associated with shipping.

Sustainable carton materials often include recycled content and certifications such as the Forest Stewardship Council (FSC) label, which guarantees that the paper comes from responsibly managed forests. Research from the Paper and Packaging Board indicates that using recycled paper in packaging can reduce greenhouse gas emissions by up to 60% compared to using virgin materials. Furthermore, many companies are shifting towards biodegradable coatings and inks to further enhance sustainability, making a significant impact on the overall environmental footprint of shipping logistics.

Additionally, the durability of carton materials plays a crucial role in their environmental impact. High-quality, sturdy cartons are less likely to get damaged in transit, which reduces the need for secondary packaging and helps decrease waste. A report by the World Packaging Organisation highlights that improved packaging design could lead to a reduction of food and product waste by as much as 30%. Therefore, when selecting carton boxes, it is essential to consider not only their environmental certifications but also their overall efficiency and durability in the shipping process.

When considering the various suppliers for carton boxes, it’s essential to analyze the costs and benefits associated with each option to determine which best fits your shipping needs. The first step is to evaluate the material quality and durability of the boxes offered. Higher quality materials may cost more upfront but can provide better protection during transit, potentially saving money on damaged goods and returns. Understanding the strength and compatibility of different box types with your products can lead to more informed purchasing decisions.

Furthermore, pricing models vary significantly among suppliers, often including factors such as bulk discounts, shipping costs, and lead times. Some suppliers may offer lower base prices but charge more for expedited shipping or additional services. It's important to calculate the total cost of ownership, factoring in these hidden expenses, to accurately gauge the financial implications of each supplier. Conducting a comparative analysis not only reveals the most cost-effective options but also highlights the value-added services that can enhance your shipping efficiency and overall customer satisfaction.