In the ever-evolving world of logistics and shipping, the choice of packaging material can significantly impact both the efficiency of operations and the satisfaction of customers. A report from Smithers Pira estimates that the global demand for carton boxes is expected to reach $293 billion by 2025, reflecting a shift towards sustainable and efficient shipping solutions. As companies increasingly recognize the importance of protecting their products while minimizing environmental impact, the selection of the right carton boxes becomes crucial.

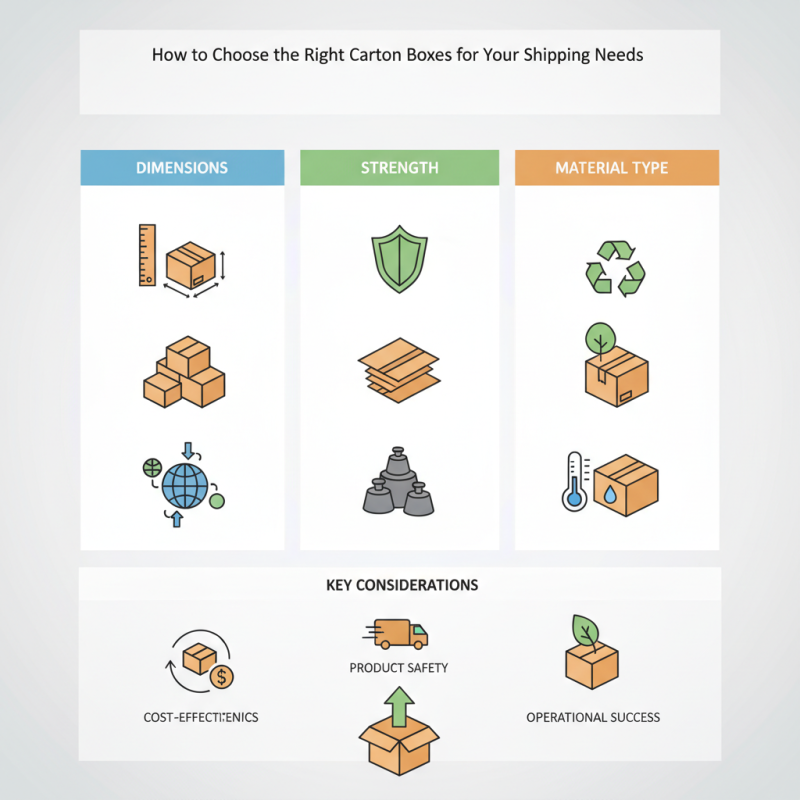

Industry expert John Smith, a leading figure in packaging solutions, emphasizes this need, stating, "Choosing the right carton boxes not only ensures product safety during transit but also enhances the overall customer experience." With a multitude of options available, businesses must consider various factors including dimensions, strength, and material type to find the optimal packaging solution. This decision-making process is essential for maintaining competitiveness in a market that demands both high-quality service and sustainability.

As we delve deeper into the specifics of selecting carton boxes for shipping needs, we will explore the critical elements that influence this choice and provide guidance on how to navigate the complexities involved. Understanding these fundamentals will empower businesses to make informed decisions that ultimately lead to greater operational success.

When selecting the right carton boxes for your shipping needs, several critical factors come into play. First and foremost, consider the dimensions and weight of the items you are shipping. The box should fit snugly around the product to minimize movement during transit, which can help prevent damage. Additionally, assess the weight of the boxes themselves; lighter options may reduce your overall shipping costs, especially for larger shipments.

Another essential consideration is the strength and durability of the carton box. Different types of cardboard are designed for various levels of protection. For instance, if you’re shipping fragile items, opt for double-walled boxes that offer enhanced insulation against impacts. Understanding the weight capacity of the box and ensuring it matches your shipping requirements can further safeguard your products.

Tips: Always perform a drop test before finalizing your choice. This involves dropping a sealed box from a height that simulates the shipping process to see if it maintains its integrity. Moreover, utilize packing materials like bubble wrap or foam inserts for added protection when shipping delicate items. By carefully considering these factors, you can ensure your products arrive safely at their destination while optimizing shipping efficiency.

When selecting the right carton boxes for shipping, it’s essential to understand the various types available and their suitability for different products.

Regular slotted containers (RSC) are among the most commonly used carton boxes. They offer a versatile option ideal for shipping items like books, clothes, and electronics. Their design allows for easy assembly and provides sufficient cushioning for lightweight to moderately heavy items.

For products that require extra protection, such as fragile goods or perishables, double-walled boxes are a suitable choice. These boxes are constructed with two layers of corrugated cardboard, enhancing their strength and durability. They are excellent for heavier items that need a higher level of security during transit.

On the other hand, if you’re shipping irregularly shaped products, custom-designed boxes become necessary. These can be tailored to fit specific dimensions and provide optimal protection, ensuring that the products remain safe and secure throughout the shipping process.

When selecting the right carton boxes for shipping, understanding box strength is crucial for ensuring product safety during transport. Two common metrics to assess box strength are the Burst Test and the Edge Crush Test (ECT). The Burst Test measures the maximum pressure a box can withstand before bursting. According to the Fiber Box Association, a box with a burst strength of at least 200 pounds per square inch (psi) is ideal for standard shipping applications, providing robust protection for various products.

On the other hand, the Edge Crush Test evaluates the strength of the box's edge, which is critical during stacking and load-bearing. ECT ratings typically range from 32 to 44 ECT for most shipping applications. A box rated at 32 ECT can support around 200 pounds of vertical load, making it suitable for lighter goods, while 44 ECT boxes are better for heavier items. Understanding these ratings helps shippers choose the appropriate box for their specific shipping needs, ensuring that products arrive at their destination undamaged and intact.

When selecting the right carton box for shipping, understanding dimensions and weight limits is crucial. The first step in this process is to accurately measure the items you plan to ship. It's essential to consider not only the length, width, and height of the products but also any additional packaging materials that will be included, such as bubble wrap or packing peanuts. This ensures that the carton box you choose will provide adequate space without being excessively large, which could lead to additional shipping costs.

In addition to sizing, it's important to assess the weight limits of your chosen box. Every carton box has a maximum weight capacity that should not be exceeded to avoid damaging the contents or risking breakage during transit. Be mindful of the combined weight of the items plus packaging materials. Additionally, consider the fragility of the items; heavier, fragile products may require more robust boxes designed to handle impact and support their weight effectively. By taking the time to get the sizing and weight limits right, you can ensure that your shipping process is efficient and secure.

When it comes to shipping, selecting the right carton boxes can significantly impact cost efficiency. Different materials offer varying levels of durability and protection, and understanding these differences can help businesses make informed decisions. For instance, while single-wall corrugated boxes may be less expensive, they may not provide sufficient protection for heavy or fragile items. Investing in double-wall boxes, though pricier, can reduce the risk of damage during transport, ultimately saving money on replacements and customer dissatisfaction.

Additionally, box quality plays a crucial role in shipping efficiency. High-quality cartons are often designed for specific shipping environments and can withstand external pressures such as moisture, temperature fluctuations, and rough handling. By choosing robust materials that meet the demands of their shipping methods, businesses can minimize losses due to damaged goods. In this regard, it is essential to conduct a thorough evaluation of shipping needs against available box options, ensuring that cost efficiency and quality are balanced for optimal performance in logistics.